Tuesday, December 20, 2011

Monday, December 19, 2011

Thursday, December 15, 2011

Tattoo Flash Buckles

It's been a long time since I've come out with any new buckles. I just listed all kinds of stuff in my Etsy Store. What do you think? Lots more to come ....

Tuesday, November 22, 2011

Black Friday Sale!!!

It's that time of the year again! Starting on Friday Nov. 25th through midnight Sunday Nov. 27th, enter coupon code BLACKFRIDAY for 15% off your entire order, plus free shipping to the US and Canada!

Thursday, November 17, 2011

Friday, November 11, 2011

When your leather belt falls apart, come get one of these bad boys

http://www.etsy.com/listing/65889865/industrial-belt-15-inch-snap-belt

All leather belts have a lifespan if you wear them every day. Especially the craptastic factory made ones most people on Etsy are selling. We used to sell those, too, but got tired of replacing them when our customers told us they had fallen apart a month later. So we went back to the drawing board and created the toughest belt of them all.

Also, my next door neighbor is a cow named Pancho. He's really smart and you can walk him around on a leash like a dog. If you say his name, he moos back at you. So cute. Just sayin'.

Labels:

belt buckle,

birthday,

blacksmith,

christmas,

fashion,

for her,

for him,

gifts for girls,

gifts for guys,

industrial,

leather belt,

men,

metalogical,

pvc belt,

vegan belt,

women,

xmas

Tuesday, November 1, 2011

Wednesday, September 21, 2011

Wednesday, August 31, 2011

Friday, August 19, 2011

New business card holders

I haven't posted any blacksmithing for a while, so I thought I'd post a quick tutorial on how I make my new business card holders. Alrighty then ...

First I start with a 2" piece of steel channel and cut it partway through the middle like so ...

The key is in the quench - too little and the metal will deform and become a twisted mess, too much and the metal will be too brittle when I bend it and split instead of making a nice bend. Here goes the bending. You have to move pretty fast or you'll lose the heat. I check my bend against a test piece while I'm bending it.

Mmmkay,now that we have the bending done, I put everything in my finishing machine to remove all the scale and rust (lots of rust here in S. Florida). Here's what they look like after a short run in the machine. You can see the scale starting to come off.

Here's what everything looks like when it comes out. A few of the pieces have a hibiscus motif chiseled into them, but that's another tutorial ...

Finally, it's time to join the parts together via the electric welder ...

Voila! Here's the finished product (well, after another couple rounds in the finishing machines and clear coat spraying):

The business card holders are available here and here if you're interested. Thanks for hanging out in my little corner of the art world! Stay tuned for more new products...

First I start with a 2" piece of steel channel and cut it partway through the middle like so ...

I also cut some pieces of 2" X 3/16" flat bar stock (not pictured) to use as the backs of the card holders. The next step is heating the pieces in my propane forge. It kind of hard to see, but the metal in the picture below is red hot. What I am doing here is quenching both ends in a can of water so that I can bend it in the vice without losing too much of its shape.

The key is in the quench - too little and the metal will deform and become a twisted mess, too much and the metal will be too brittle when I bend it and split instead of making a nice bend. Here goes the bending. You have to move pretty fast or you'll lose the heat. I check my bend against a test piece while I'm bending it.

Mmmkay,now that we have the bending done, I put everything in my finishing machine to remove all the scale and rust (lots of rust here in S. Florida). Here's what they look like after a short run in the machine. You can see the scale starting to come off.

Here's what everything looks like when it comes out. A few of the pieces have a hibiscus motif chiseled into them, but that's another tutorial ...

Finally, it's time to join the parts together via the electric welder ...

Voila! Here's the finished product (well, after another couple rounds in the finishing machines and clear coat spraying):

The business card holders are available here and here if you're interested. Thanks for hanging out in my little corner of the art world! Stay tuned for more new products...

Labels:

blacksmithing,

business card holders,

desktop art,

flower,

forged,

hibiscus,

metal,

steel,

tropical fruit,

welding

Friday, July 8, 2011

Business card holders and containers

Another great organization I've been fortunate enough to work with is the World Steel Association. Here are pictures of some business card holders with their logo hot stamped on them and some containers. They give these items out as gifts to their contacts in the steel business. They are working hard to keep the steel industry at the cutting edge in areas like sustainability, but they also help preserve the oldest profession in the steel industry, blacksmithing, by supporting artists like me.

These business card holders have turned out to be difficult little projects when you are trying to keep them all identical. I have a new design that I will be posting up soon and I am working on more business card holders as well as containers, so stay tuned!

These business card holders have turned out to be difficult little projects when you are trying to keep them all identical. I have a new design that I will be posting up soon and I am working on more business card holders as well as containers, so stay tuned!

Friday, June 24, 2011

Surfrider buckles up and running!

I'm excited to say that the Surfrider Foundation liked the buckles I made for my friend so much, they have decided to include them in their product line. Check them out here.

If you haven't heard of the Surfrider Foundation, be sure to check out their website. Their goal is to protect oceans, waves, and beaches worldwide. Recent events like the Gulf oil spill and the nuclear crisis at Fukushima illustrate just how badly our oceans need protection in today's world.

The buckles pass the Surfrider Foundation's sustainability requirements, so, in addition to supporting an important cause and buying handmade, you can feel great about this product's low impact on the environment. Here's a video of the manufacturing process:

Wednesday, June 22, 2011

Monday, June 13, 2011

Saturday, June 4, 2011

Monday, March 14, 2011

Odds and Ends

One of the jaws on the tongs I use to make buckles broke the other day, so I had to make a new pair. It was kind of sad, because they were the first pair of tongs I ever made. But, I made them a little too thin and years of being heated, quenched, and beaten on finally did them in. I made a mistake on the new pair. Notice how the old pair has a nice taper on the reins (what blacksmiths call the handles) and the new ones don't. Yeah, I kind of forgot they don't handle right without being tapered. They work great, but feel just a bit heavy, so sometime I'll have to take them apart and taper them. Man, I need a power hammer.

I've been trying to think of a use for the plug that's left over from the hole I chisel in the bottle opener buckles for a long time. I usually just save them in cans and leave them out for the scrap metal guys, but I thought it would be cool to make them into some sort of scrap metal art. So, I came up with these skull pendants. I'm going to list them soon in the store and they will be under 10 bucks!

I am working on an order of containers for a client in the steel industry who gives them out as corporate gifts. They are almost done now, but here is a progress picture from last week:

I've been trying to think of a use for the plug that's left over from the hole I chisel in the bottle opener buckles for a long time. I usually just save them in cans and leave them out for the scrap metal guys, but I thought it would be cool to make them into some sort of scrap metal art. So, I came up with these skull pendants. I'm going to list them soon in the store and they will be under 10 bucks!

| ||||

| These haven't been cleaned and finished yet |

Wednesday, February 9, 2011

My new old motorcycle

I finally finished off my 1978 XT500 project. For now anyway. It's a super fun bike, especially with all the dirt roads around here. I stripped it down to the frame, removed the stuff I didn't need, and changed a few things. I also reworked a smaller tank to fit the frame, made a seat pan and had it upholstered, and modified the stock exhaust. There are a few other custom parts here and there, and pretty much everything that doesn't make it go or stop is gone other than the head and tail lights.

Tuesday, January 25, 2011

Surfrider Foundation Buckles

A good friend of mine works for the Surfrider Foundation in Oregon. The Surfrider Foundation is a non-profit grassroots organization dedicated to the protection and enjoyment of our world’s oceans, waves and beaches. Check out their website here:

http://www.surfrider.org/default.aspx

He wanted some buckles with their new logo to give out as gifts to his friends. So, rather than have the logo laser cut like most people do these days, we decided to do some old school manufacturing instead. We had a stamp custom made and I hand stamped each buckle using my flypress. I think stamping creates a really unique look, and it's a lot more fun than just punching some buttons on a computer. Check out a video of the buckles being made here:

http://www.youtube.com/watch?v=LbVcdOGzwaQ&feature=feedu

Friday, January 14, 2011

New Belts!

I am so excited to introduce our new line of industrial grade super duper tough belts! Strong enough for the Florida sugar cane factories, and definitely tough enough to hold up your pants for a long time to come!

I had always intended to replace the commercial belts we have been selling with something handmade. Initially, when I started the buckles and they began to take off, I just wanted something I could sell with my buckles to hold people's pants up. But, over time I noticed that the quality was not always the best, and I was tired of pairing the buckles with a non-handmade product.

When I first started brainstorming, I just assumed I would be working with leather. But, I'm a big animal lover, and my house out here in the Everglades is surrounded by cow fields. The cows are like my neighbors, and I would have a hard time looking at them day in and day out while I was slicing up their friends' hides to make into clothing. To tell you the truth I'm not a vegan or vegetarian, but I have a lot of friends who are, and I often hear them mention the lack of choices when it comes to normal clothing items like belts or shoes. I decided to find another material and it just so happened that a friend of a friend has a job selling industrial belting products!

Perhaps you are thinking, "But, I'm used to leather and these are more expensive than your other belts, why should I buy one of these?" Well, for starters, everyone else has a leather belt, so right off the bat, you'll have something cooler and different than everyone else. These belts are also tougher than leather, and won't stretch and wear out the way leather does. How do I know they are tougher than leather? Well, I looked through two huge books of belting samples for industrial applications and there wasn't a single one made of leather. When was the last time you saw a belt driven motorcycle with a leather belt or industrial tools that use leather belting? Been a while, right?

Perhaps you are thinking, "But, I'm used to leather and these are more expensive than your other belts, why should I buy one of these?" Well, for starters, everyone else has a leather belt, so right off the bat, you'll have something cooler and different than everyone else. These belts are also tougher than leather, and won't stretch and wear out the way leather does. How do I know they are tougher than leather? Well, I looked through two huge books of belting samples for industrial applications and there wasn't a single one made of leather. When was the last time you saw a belt driven motorcycle with a leather belt or industrial tools that use leather belting? Been a while, right?

So, if you are in the market for a new belt, make sure you check these out! Keep an eye out because we will have more new belt designs and materials on the way!

www.metalogical.etsy.com

I had always intended to replace the commercial belts we have been selling with something handmade. Initially, when I started the buckles and they began to take off, I just wanted something I could sell with my buckles to hold people's pants up. But, over time I noticed that the quality was not always the best, and I was tired of pairing the buckles with a non-handmade product.

When I first started brainstorming, I just assumed I would be working with leather. But, I'm a big animal lover, and my house out here in the Everglades is surrounded by cow fields. The cows are like my neighbors, and I would have a hard time looking at them day in and day out while I was slicing up their friends' hides to make into clothing. To tell you the truth I'm not a vegan or vegetarian, but I have a lot of friends who are, and I often hear them mention the lack of choices when it comes to normal clothing items like belts or shoes. I decided to find another material and it just so happened that a friend of a friend has a job selling industrial belting products!

Perhaps you are thinking, "But, I'm used to leather and these are more expensive than your other belts, why should I buy one of these?" Well, for starters, everyone else has a leather belt, so right off the bat, you'll have something cooler and different than everyone else. These belts are also tougher than leather, and won't stretch and wear out the way leather does. How do I know they are tougher than leather? Well, I looked through two huge books of belting samples for industrial applications and there wasn't a single one made of leather. When was the last time you saw a belt driven motorcycle with a leather belt or industrial tools that use leather belting? Been a while, right?

Perhaps you are thinking, "But, I'm used to leather and these are more expensive than your other belts, why should I buy one of these?" Well, for starters, everyone else has a leather belt, so right off the bat, you'll have something cooler and different than everyone else. These belts are also tougher than leather, and won't stretch and wear out the way leather does. How do I know they are tougher than leather? Well, I looked through two huge books of belting samples for industrial applications and there wasn't a single one made of leather. When was the last time you saw a belt driven motorcycle with a leather belt or industrial tools that use leather belting? Been a while, right?

So, if you are in the market for a new belt, make sure you check these out! Keep an eye out because we will have more new belt designs and materials on the way!

www.metalogical.etsy.com

Labels:

cool belts,

industrial,

pvc,

vegan belt,

vegetarian

Friday, January 7, 2011

Eric's Shop

Here are some pictures of my friend Eric Velleca's blacksmith shop. We met when I moved down to Florida and called him with some questions about the area. Eric is thinking of moving out of state, so I wanted to post some pics of his cool shop in case he moves. There aren't that many parts of the country where you can have an open air, tropical blacksmith shop like this. Eric is a really talented blacksmith who does a lot of large architectural work. You can check out his website here: http://www.vellecametaldesign.com/

Power hammers for forging steel:

Forges, quenching bucket, and anvil:

Another shot of the anvil with an industrial press and tong rack in the background:

Gas forge:

Drill press:

Seems like no metal shop is complete without at least one motorcycle project. Here are a Harley and Honda CB 750 Eric is building:

CB750:

Large gate:

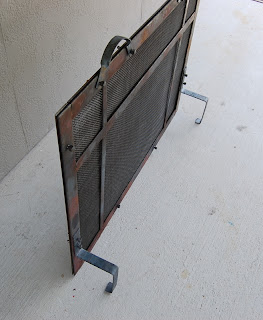

Samples:

Here's a picture of Eric's sweet custom Toyota Landcruiser which he built. There are a lot of cool custom parts, but unfortunately the interior pics didn't come out very well:

Power hammers for forging steel:

Forges, quenching bucket, and anvil:

Another shot of the anvil with an industrial press and tong rack in the background:

Gas forge:

Drill press:

Seems like no metal shop is complete without at least one motorcycle project. Here are a Harley and Honda CB 750 Eric is building:

CB750:

Large gate:

Samples:

Here's a picture of Eric's sweet custom Toyota Landcruiser which he built. There are a lot of cool custom parts, but unfortunately the interior pics didn't come out very well:

Subscribe to:

Comments (Atom)